Get to Know: Types of Advanced Welding Technology

📆 2021-07-19

Welding is the application of heat on metals to repair or make structures, machines, or equipment. Workers use technology through welders, cutters, shapers, measuring instruments, and many other welding machines. They also organize, operate, and maintain welding equipment. Nowadays there are many technologies in the welding process that is developed and sophisticated. So, what are the types of technology? Here are some types of welding technology that you need to know.

-

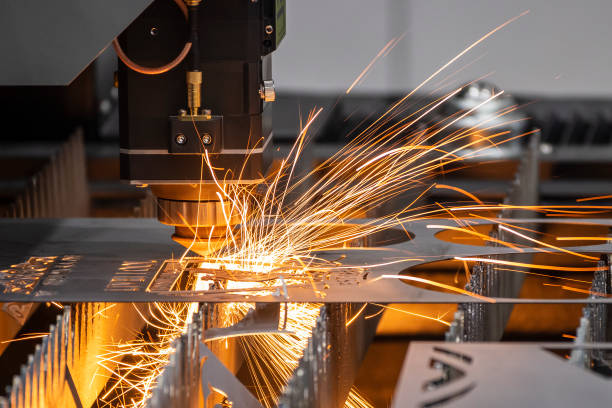

Laser Hybrid Welding

Laser hybrid welding is a combination of laser beam welding and MIG welding technology, which can obtain the best welding effect, fast welding speed, and bridging welding capability. This is the most advanced welding method in this era. The advantages of laser hybrid welding are high-speed,small thermal deformation, small heat affected areas, and ensure metal structure, also weld mechanical properties. -

Friction Stir Welding

Friction stir welding uses frictional heat and heat plastic deformation as a source of heat welding. Friction stir welding is the process of inserting a cylinder pin or other shape such as a threaded cylinder into the working body joint. This type of welding can be used to weld different materials, such as metal, ceramic, plastic, etc. This welding has the advantages of high welding quality, fewer defects, easy mechanization, automation, stable quality and high cost efficiency. -

Electron Bean Welding

Electron beam welding (EBW) is a type of welding method that uses the resulting heat energy by accelerating and focusing electron beams that bombard welds in vacuum or nonvacuum. EBW is widely used in space, atomic energy, national defense and military industries, automobiles, electrical instruments and many other industries due to its advantages without electrodes, without oxidation, good process repetition, and small thermal deformation. -

Ultrasonic Metal Welding

Ultrasonic metal welding is a special method to connect the same metal or different metals by using mechanical vibrational energy of ultrasonic frequencies. Advantages of fast ultrasonic metal welding, energy saving, high fusion power, good conductivity, no sparks, and close to cold processing.

Currently, Duta Laserindo Metal has used advanced technology in the fabrication process including in the welding process. Welding process is very important in metal fabrication process. If you need the best welding process on your metal, our Laserindo Metal Ambassador can help meet all your metal fabrication needs.

別の記事

An Important Factors Affecting Laser Cutting Quality

The most important factors affecting the quality during the laser cutting process: surface treatment, the basic microstructure of the material, quality and surface roughness...

略さずに →

Advantages of Using Automatic Punching Machines Than Traditional

Advantages of automatic punching machine: Stable high precision, reliable and safe operation, automatic production, slider adjustment mechanism, novel design and environmental protection...

略さずに →