Ways to Resist Porosity in Aluminum Alloy Laser Welding

📆 2021-07-19

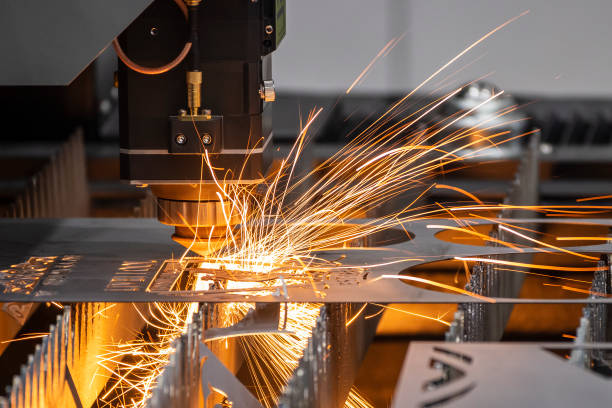

Laser welding is a technology that emits a high-intensity laser onto a metal surface and causes the metal to melt and crystallize to form a weld by thermal coupling between the laser and the metal. According to the thermal mechanism of laser welding, it can be divided into thermal conduction welding and deep penetration welding.

Thermal conductive welding is mainly used in package welding or micro-nano welding of precision parts. Penetration welding in lasers is mainly used in welding materials that require complete penetration. The welding process will make the material evaporate and a keyhole phenomenon appears in the molten pool. It is the most widely used laser welding method today, and is also the preferred aluminum alloy welding method. Then how to resist porosity in aluminum alloys in the laser welding process? Here are some ways that can be done, including:

-

Inhibition of welding porosity by surface treatment before welding

Surface treatment before welding is an effective method for controlling metallurgical pores in aluminum alloy laser welding. Generally, surface treatment methods include physical mechanical cleaning and chemical cleaning. After being compared, the best process is chemical treatment, namely metal cleaning, water washing, alkaline washing, water washing, acid washing, water washing, and finally drying drying). After surface treatment, the test plate should be welded within 24 hours. When the test plate lasts a long time after treatment, the assembly should be cleaned with absolute alcohol before welding. -

Control welding porosity by selecting the right shielding gas and flow rate

The selection of shielding gas directly affects the quality, efficiency and cost of welding. In the laser welding process, the correct blowing of the shielding gas can effectively reduce the porosity of the weld. Too much gas flow is accompanied by too much gas pressure, which makes part of the shield gas mixed into the solution pool and makes the porosity increase. -

Controlling welding porosity with welding process parameters

The formation of weld porosity is not only related to the quality of the weld surface treatment, but is also related to the welding process parameters. The influence of welding parameters on weld porosity is mainly reflected in weld penetration, namely the effect of the ratio of the width of the weld back on the porosity of the weld.

Influenced by the properties of the aluminum alloy itself, the phenomenon of no porosity cannot be completely avoided in the welding process, only the porosity can be reduced. Through process optimization before and after welding and a summary of the experiment, Duta Laserindo Metal uses several efficient ways to inhibit porosity, which can be used so that it can meet all your needs with the best and efficient results.

別の記事

What are the Main Technical Indexes of Driving Methods in Laser Cutter?

The main technical indexes of driving methods in laser cutters: Stroke, positioning accuracy, repositioning accuracy, drive, transmission rigidity....

略さずに →

An Important Factors Affecting Laser Cutting Quality

The most important factors affecting the quality during the laser cutting process: surface treatment, the basic microstructure of the material, quality and surface roughness...

略さずに →