How to Adjust the Focus on a Laser Cutting Machine?

📆 2021-06-15

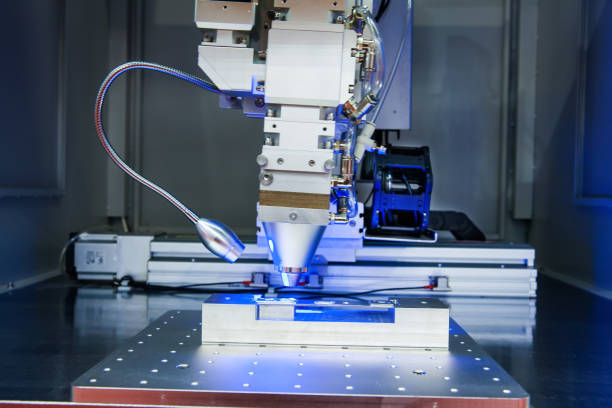

Laser cutting is a thermal process in which a focused laser beam is used to melt material over an area. Continuous cutting is produced by moving a laser beam or workpiece under CNC control. There are three main types of laser cutting namely fusion cutting, flame cutting and remote cutting.

Then how to adjust the focus on the laser cutting machine? There are several methods or methods that can be used, including the following:

1. NC point location from laser focus position

Take a flat, smooth sheet of white cardboard and place it on the workbench. The laser cutting head will be installed on it. The height of the cardboard focusing lens is about 10mm, which is smaller than the focal length of the focusing lens.

The numerical control system sets the cutter head to move every 10mm along the X or Y axis, and the Z axis goes up 1mm during each movement, and the distance for 20 consecutive moves can be set. Each time it moves into position, 20 holes are punched by 20 times, and the Z-axis height is increased by 20 mm.

By observing 20 holes, we can find that the diameter of the holes gradually changes from large to small, and then from small to large. Find the location where the aperture is smallest, and record. The distance from the cardboard to the lens when measured at this position is the actual focal position of the laser beam.

2. Bevel focus cautery method

The method is shown by placing a straight wooden plank diagonally on a workbench with an inclination of about 10 degrees, then setting the cutting head at point A. The point A height dimension of the focusing lens is 20mm smaller than the focal length of the focusing lens. The numerical control system regulates the cutter head to move horizontally along the X axis or Y axis continuously for 230mm.

The laser emits a 200W continuous laser when the movement starts. When the cutting head stops, the laser also stops. At this time, you can see that there is a laser burn trail that goes from wide to narrow, then from narrow to wide

Take the narrowest point of the trail as the focus position, take notes. At this position, the distance of the wooden plank from the lens is the actual focus position of the laser beam.

Those are some ways or methods that you can do to adjust the focus on the laser cutting machine. Duta Laserindo Metal always provide the best cutting results because we focus on very precise lasers so that the cutting results on metal are very precise and according to your wishes.

別の記事

Get to know MOPA Laser Marking in Metal Marking Process

The MOPA laser marking machine is very similar in design and outlook to fiber laser marking...

略さずに →

Perfect Configuration of TruMark Station 5000 Machine in Laser Marking Process

Perfect Configuration and advantages of TruMark Station 5000 adaptable and ergonomic, very safe, universally usable, Multiple focus lenses, great compatibility and open to everyone...

略さずに →