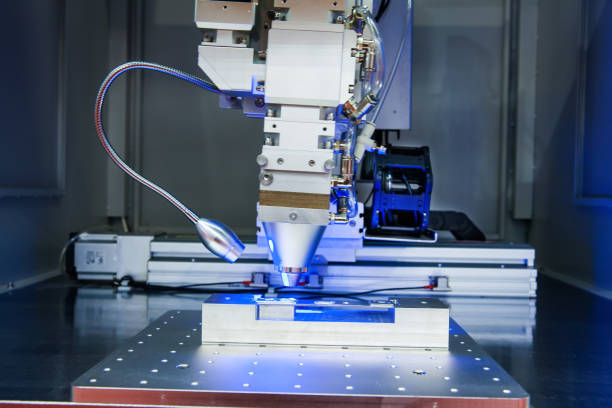

Welding Process Problems and Solutions

📆 2021-05-24

Although there is no such thing as a technical secret in the welding process, there are many welding technologies, methods and processes in the welding process that can actually simplify the welding process, this process is called technical knowledge. There are some problems that commonly occur in the welding process and the solutions include the following:

-

When welding steel workpieces with GMAW and FCAW, what if the thickness of the workpiece exceeds the welder's maximum welding current? The solution is to preheat the metal before welding. Propane, standard gas, or acetylene torches are used to preheat the workpiece welding area. The preheating temperature is 150 ~ 260 ℃, and then welding is carried out. The purpose of preheating the metal in the welding area is to prevent the weld area from cooling down too quickly, so as not to create weld cracks or imperfect fusion.

-

If it is necessary to weld a thin metal cover on a thick steel pipe with GMAW or FCAW, the welding current cannot be adjusted properly, and two situations can occur: First, in order to prevent the thin metal from burning and reduce the welding current, the thin metal covering cannot be welded to the thick steel pipe at this time. Second, the welding current will burn the thin metal cover. What's the solution? You can adjust the welding current to avoid burning through the thin metal cover. At the same time, heat the thick steel pipe with a welding torch, then weld the two metal structures by means of a thin plate welding process. Adjust the welding current to suit thick steel pipe welding. During welding, the residence time of the welding arc on thick steel pipes must be kept at 90%, and the residence time on the thin metal covering should be reduced. It should be pointed out that only by mastering this technique good welded joints can be obtained.

-

If it is necessary to weld a material containing galvanized or chrome to another part, what should be done? The best process is to file or grind the area around the weld before welding, as sheet metal containing galvanized or chromium will not only contaminate and weaken the weld, but also release toxic gases during welding.

Those are some of the problems that may occur in the welding process. Knowledge of welding can save time, cost and labor, and even determine welding success and failure, profit and loss. Duta Laserindo Metal has the best technicians and professionals in the field of welding so that they can help you to produce the best product for the welding process you need.

別の記事

Matters Affecting Sheet Metal Bending Radius

Metal bending is a process in which metal can change shape when applying a force to a subject...

略さずに →

Get to know MOPA Laser Marking in Metal Marking Process

The MOPA laser marking machine is very similar in design and outlook to fiber laser marking...

略さずに →