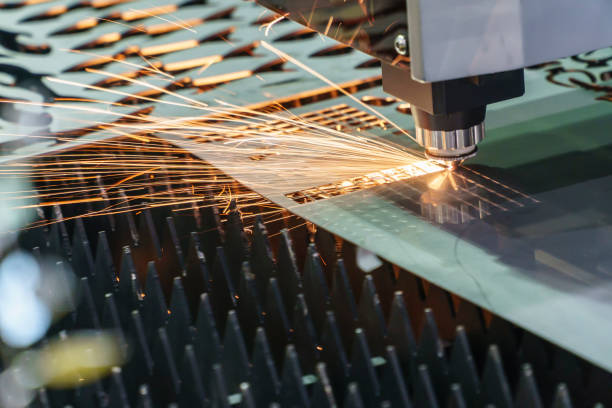

Parameters on the Laser Welding Process

📆 2021-05-17

Laser weding is a process used to join metals or thermoplastics using a laser beam to form a weld. Being a concentrated heat source, laser weding thin materials can be carried out at high welding speeds of meters per minute, and thicker materials can produce narrow and deep welds between square-edged sections. In doing laser weding, there are several parameters that must be considered, including:

-

Power density

Power density is one of the most important parameters in laser processing. With a higher power density, the surface layer can be heated to boiling point in a microsecond time span, resulting in large amounts of evaporation. Therefore, the high power density is beneficial for material moving processing, such as drilling, cutting and engraving. For lower power densities, it may take a few milliseconds for the surface temperature to reach the boiling point. Before the surface layer evaporates, the bottom layer reaches a melting point, which is easy to form a good fusion weld. Therefore, in conduction weding lasers, the power density is in the range 104 to 106 W / cm2 -

Laser pulse waveform

Laser pulse waveform is an important problem in laser weding, especially for sheet metal welding. When high-intensity laser light hits the surface of the material, 60 to 98% of the laser energy on the metal surface is reflected and lost, and the reflectivity changes with the surface temperature. -

Laser pulse width

The pulse width is also one of the important parameters of laser pulse welding. This is also a fairly important parameter of material moving and material melting. Apart from that it is also the main parameter that determines volume, equipment and costs. -

The effect of the amount of blurring on the quality of the weld

Laser weding usually requires a certain amount of blurring, because the power density of the center of the point at the laser focus is too high, and it easily evaporates into holes. The power density distribution is relatively uniform over the plane away from the laser focus. There are two modes of blurring, positive blurring and negative blurring. If the focal plane is above the workpiece, it is positive defocusing, otherwise negative defocus.

The discussion above is a number of parameters in the laser welding process. Duta Laserindo Metal provides welding process services for your sheet metal fabrication process. For more information about what parameters and processes are used at Duta Laserindo Metal, you can contact us to get services according to your needs.

別の記事

Methods To Increase Efficiency in Laser Cutting

The laser cutting machine is the industry's most advanced plate processing equipment. In the actual production process...

略さずに →

Solutions to Sheet Metal Bending Problems

Sheet metal bending and forming is performed on a plate bending machine. Put the workpiece on the plate bending machine...

略さずに →