Methods To Increase Efficiency in Laser Cutting

📆 2021-05-17

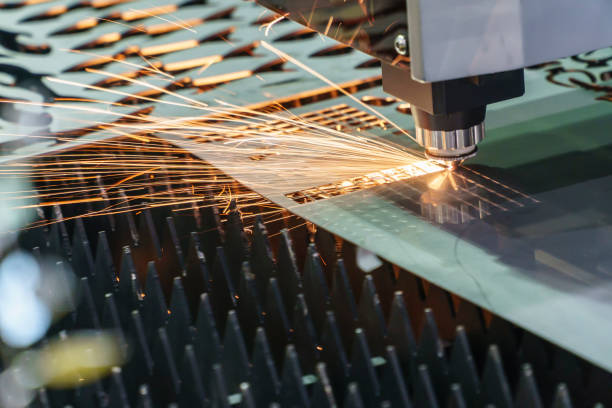

The laser cutting machine is the industry's most advanced plate processing equipment. In the actual production process, the cutting method directly determines the production efficiency and quality of the workpiece. Therefore, it is necessary to explore effective cutting skills in order to increase production efficiency and product quality as well as reduce plate wastage rates. Here are some cutting techniques that have been fully verified in the production process including:

-

Perforation is concentrated

Centralized perforation, also known as pre-perforation, is actually a type of processing technology not available in conventional laser cutting equipment. For example, when laser cutting a thick plate, each contour of the cutting process must go through two stages of perforation and cutting. -

Application of micro connection

During laser cutting, the sheet metal is held in place by a serrated support rod. If the cut part is not small enough, it cannot fall out of the gap in the support blade. If it is not large enough, it cannot be supported by the support bar, then it may lose balance and the workpiece may warp. However, this kind of problem can be avoided by using microsurgery cutting technology. The specific method is that when programming the laser cutting on the image, the closed contours are deliberately broken in several places, so that after cutting, the parts and surrounding materials will stick together and will not fall off, and these damaged places are called micro-connections. -

Selection of piercing point in laser cutting

In the laser cutting process, after the laser beam continuously shines on the material, a hole is formed in the center, and then the coaxial air flow with the laser beam will quickly remove the liquid material and form a small hole. This hole is similar to the threaded hole in WEDM. The laser beam takes this hole as a starting point for contour cutting. Generally, the direction of the laser beam in the flight path is perpendicular to the direction of the tangent to the cutting contour of the machine part.

Conclusion

In the actual production process, the operation of a laser cutting machine is quite complex, with a variety of workpieces and materials. As cutting technology matures, with skillfully, Duta Laserindo Metal use all kinds of cutting skills and accumulate experience in solving problems, we can increase the capacity of experts, equipment and production processing.

別の記事

Get to know CO2 Laser Marking in Metal Marking Process

A CO2 laser marking machine is typically a closed tube laser marking system with a galvo steering beam...

略さずに →

Parameters on the Laser Welding Process

Laser weding is a process used to join metals or thermoplastics using a laser beam to form a weld...

略さずに →