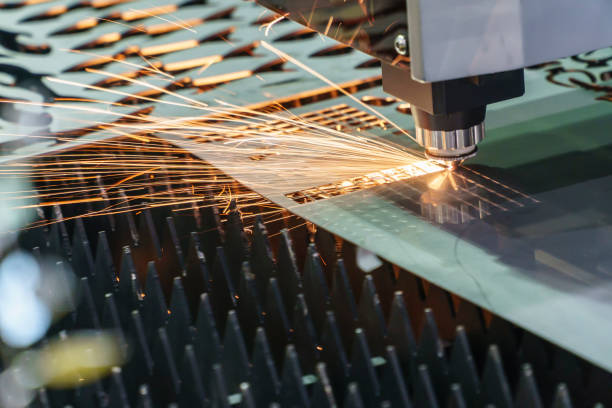

Get to know CO2 Laser Marking in Metal Marking Process

📆 2021-05-17

A CO2 laser marking machine is typically a closed tube laser marking system with a galvo steering beam designed to mark non-metallic surfaces such as wood, glass, quartz, and ceramics. This machine is used to make bar codes, serial numbers, and logos on metal and other surfaces. When lasers mark bare metals using a CO2 laser, a special marking material is used to treat the metal prior to engraving. After the laser beam is applied, the heat from the laser binds the marking agent to the metal, producing a high contrast permanent mark.

The engine is fast and affordable. They are among the oldest types of engravers and markers, and can also mark organic materials such as wood, ceramics such as tiles, stone and more. The CO2 laser system can be operated from a variety of applications such as Windows and Linux, and is very easy to use.

Application

CO2 lasers are mostly used in food, pharmaceutical or alcohol packaging, integrated circuits, electrical equipment, cellular communications, microchips, and electronic components. Due to their wavelength, sealed CO2 laser sources achieve the best marking results on organic materials such as wood, paper or leather and certain plastic polymers. The CO2 laser is also suitable for some glass marking.

Advantages

-

Good for coated metal, such as painted aluminum or brass paint, does not require pre-treatment.

-

CO2 lasers are best suited for non-metals, producing good marks on materials such as wood, leather, paper, plastics, glass, ceramics and acrylics.

Deficiency

-

If you want a CO2 laser machine with high power, it can be very expensive.

-

CO2 laser marking machines show much lower results than fiber lasers when working with metals. This is due to the time it takes for coating or pre-processing with the metal marking material.

-

CO2 laser treatment is also more expensive, and the operating requirements are higher.

One of the technologies in the marking process on sheet metal is the CO2 laser. There are several advantages and disadvantages to the process of using this laser as mentioned above. If you want to use laser marking for your products, Duta Laserindo Metal provide services for the best laser marking that can meet all your needs at an economical and reliable price.

別の記事

How to Choose a Press Machine for the Right Punching Process?

Punching is a metalworking process that is used extensively in the manufacturing industry....

略さずに →

Methods To Increase Efficiency in Laser Cutting

The laser cutting machine is the industry's most advanced plate processing equipment. In the actual production process...

略さずに →