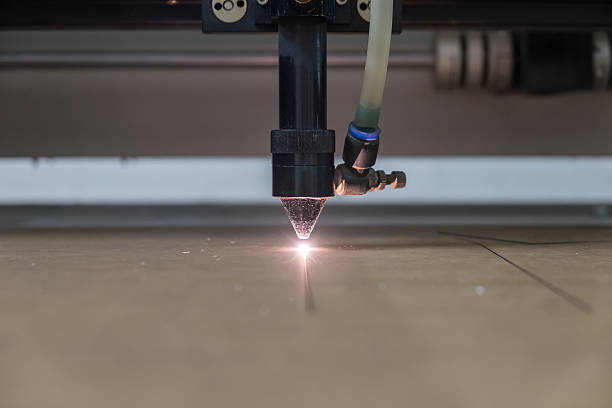

Gas Generation Trends Used in Fiber Laser Cutting

📆 2021-05-05

When fabricators use a fiber laser, they learn two things: how they will cut the material at a higher rate than they would with the older CO2 technology, and they will consume more nitrogen while doing it. Fabricators are encouraging industry to find more cost-effective alternatives to liquid nitrogen, which are contractually mandatory to purchase in bulk.

This led to three distinct laser gas trends. There are several trends in gas generation used in fiber lasers, including:

-

Nitrogen Gas

Nitrogen gas generation is not really a new trend, but it has really caught on in recent years. Technology has evolved to be more reliable, which eliminates the huge fear that the laser will shut down due to gas delivery problems. Nitrogen is the largest component of the air we breathe. It accounts for about 78 percent of air, with oxygen (20.9 percent), argon (0.9 percent), carbon dioxide (0.03 percent), and the trace elements hydrogen, helium, neon, krypton, and xenon making up the rest. -

Dry Air Assist System

Interest in dry air assist systems has really spiked over the last few years as they provide metal fabricators with an alternative gas-generating option when they don't need the bright shiny cutting edges provided by nitrogen being used as a laser cutting aid gas. They get cutting performance at no additional cost. For example, a dry air assist system has a compressor that is about half the size of a nitrogengenerating system compressor, which saves costs not only in initial investment but also in ongoing operating costs. -

Hybrid System

Mixing gases to achieve certain results is nothing new in metal fabrication. Welders have used different gas mixtures for different applications over the years. Now the concept is attracting the attention of more and more metal manufacturers looking to get the most out of their fiber laser. The gas-combining hybrid system in an exclusive manner consists of a nitrogen generator, which produces nitrogen at a higher purity level than is normally available with a standard system, and a dry air assist system.

The use of fiber laser cutting has grown rapidly compared to conventional cutting methods. Over time, several trends in the generation of gases used in fiber lasers have also continued to develop. There are many companies that provide fiber-type laser cutting services, and one of them is Duta Laserindo Metal. We can help you to ensure the effectiveness of the use of fiber lasers so as to maximize your satisfaction with our services.

別の記事

Get to know Ultraviolet (UV) Laser Marking in Metal Marking Process

Ultraviolet (UV) represents a band of the electromagnetic spectrum with wavelengths from 10 nm to 400 nm....

略さずに →

How to Choose a Press Machine for the Right Punching Process?

Punching is a metalworking process that is used extensively in the manufacturing industry....

略さずに →