Get to Know Kanban Method and How to Apply It

📆 2021-02-22

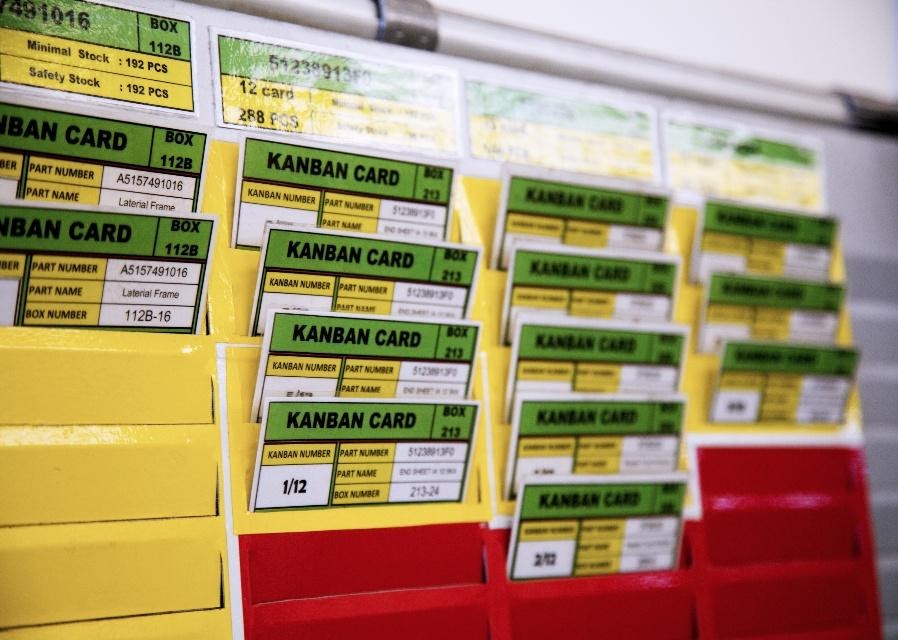

Have you ever heard about the Kanban method? Kanban comes from two Japanese words, namely “Kan” [看] which means “Seeing” or “Visual” while the word “Ban” [板] when translated becomes “Board” or “Card”. So, the term Kanban can be translated as “Visual Board” or “Visual Card”.

Kanban was developed as a method for signaling the inventory of production materials in the Inventory Just in Time system. By applying the Kanban Method, production materials are supplied and arrived on time by the required quantity thereby reducing handling and storage costs.

Kanban is known as a management method for visualizing communication and controlling the flow of activities in production, allowing everyone to see the flow and adjust it according to their needs.

The Kanban method is generally applied in companies engaged in manufacturing such as PT DLM. Nowadays, many non-manufacturing companies have implemented this method to make work series more effective and efficient. Now, let's discuss three steps and six main rules that must be followed when companies want to implement the Kanban method.

Three Steps to Implement the Kanban Method :

1. Workflow Visualization

A job is easier to monitor and supervise if it is divided into sections, subsections, or segments. The sections are then organized into a single workflow and displayed in the form of a table or work list that can be seen by stakeholders. This can be linked to a list of production materials so that it can be seen and known by them (stakeholders).

2. Limiting WIP (Work in-Progress)

Firmly stipulate limits on work, tasks, and the number of product units that are still in process. The task that has been arranged in a workflow must be completed in accordance with a predetermined time period. Thus, tasks that are still in progress can be controlled as best and as minimally as possible. Also, with this WIP limitation for products that are in the production process, the required inventory will be minimized.

3. Measure the Lead Time Required

Lead time is the cycle of time it takes to complete a job, task or product from start to finish. In the kanban method, it is necessary to measure and determine the lead time to optimize the work process. So that the completion time can be predicted as accurately as possible.

Six Key Rules for Applying the Kanban Method:

- Take only what is needed

- Produce the exact quantity required

- No Item is moved or used without the Kanban

- Never pass on defective products

- Kanban must be applied consistently on all items

- The amount of Kanban can be reduced or increased according to the needs of the production activity itself.

別の記事

What is the KANBAN Method?

Kanban is a term in Japanese which means Visual Board. Kanban is used as a method to signal the inventory of production materials in the Inventory Just in Time system. By applying this...

略さずに →

COVID-19 Guidelines for Office Workspace

The importance of a health protocol in the company is mandatory, especially during the COVID-19 era. During this pandemic, all companies must...

略さずに →