Apa Itu Metode KANBAN?

📆 2021-02-22

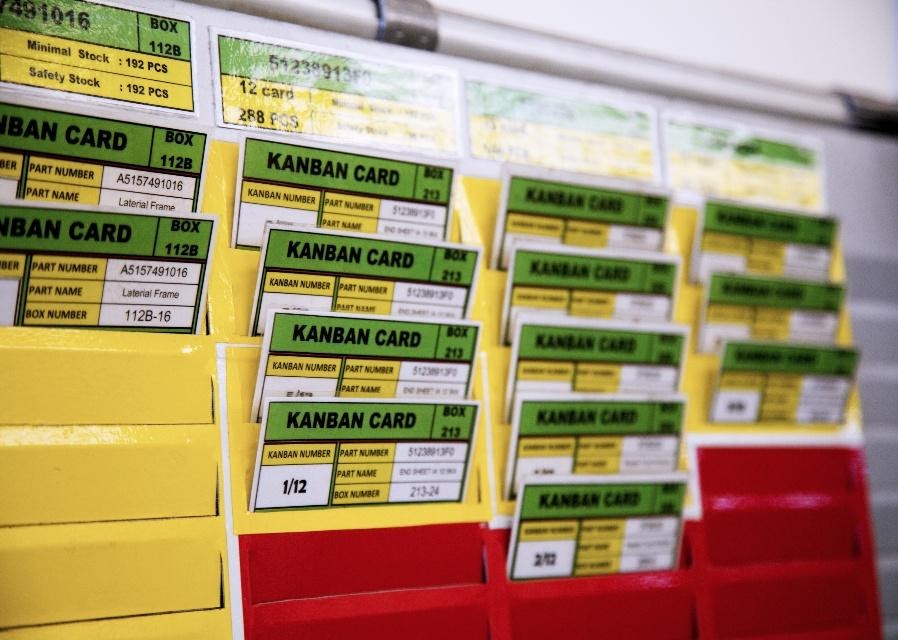

Kanban merupakan istilah dalam bahasa Jepang yang artinya adalah Papan Visual. Kanban digunakan sebagai metode untuk memberikan sinyal pada persediaan bahan-bahan produksi di sistem Inventory Just in Time (Sistem Persediaan yang Tepat Waktu). Dengan menerapkan metode ini, bahan-bahan produksi yang dipasok akan tiba pada waktunya sesuai dengan jumlah yang dibutuhkan, sehingga bisa mengurangi biaya penanganan dan penyimpanan.

Kanban berasal dari dua kata bahasa Jepang yaitu “Kan” [看] yang artinya adalah “Melihat” atau “Visual” sedangkan kata “Ban” [板] jika diterjemahkan langsung ke bahasa Indonesia menjadi “Papan” atau “Kartu”. Jadi istilah Kanban dapat diartikan / diterjemahkan menjadi “Papan Visual” atau “Kartu Visual”.

Pada dasarnya, program kanban adalah suatu metode manajemen untuk memvisualisasikan komunikasi dan pengendalian serangkaian aliran aktivitas di produksi, sehingga memungkinkan semua orang untuk melihat aliran aktivitas tersebut dan menyesuaikannya sesuai dengan kebutuhan.

Metode Kanban umumnya diterapkan di perusahaan-perusahaan yang bergerak di bidang Manufakturing, namun saat ini juga banyak perusahaan-perusahaan non-manufakturing yang menerapkan metode ini guna menciptakan aliran kerja yang efektif dan efisien.

Terdapat tiga langkah penting dalam menerapkan Metode Kanban, yaitu:

1. Visualisasi Alur Kerja

Suatu Pekerjaan akan dapat lebih mudah dipantau dan diawasi jika dibagi menjadi beberapa bagian/sub-bagian ataupun segmen. Bagian atau Segmen dari pekerjaan tersebut kemudian disusun menjadi suatu Alur kerja dan ditampilkan dalam bentuk tabel ataupun daftar kerja yang dapat dilihat oleh semua pihak yang berkepentingan (stakeholder).

Demikian juga dengan daftar bahan-bahan produksi agar dapat dilihat dan diketahui oleh semua stakeholder. Visualisasi tersebut dapat menggunakan cara yang paling sederhana, yaitu dengan menempelkan kertas post it ataupun kartu informasi yang ditempelkan di papan ataupun dengan menggunakan software khusus untuk Kanban.

2. Membatasi WIP (Work In-Progress)

Menetapkan dengan tegas batas pekerjaan/tugas ataupun jumlah unit produk yang masih dalam proses (Work In-Progress). Pekerjaan atau tugas yang telah disusun dalam Alur Kerja harus diselesaikan sesuai dengan jangka waktu yang ditentukan, sehingga pekerjaan yang tertunda ataupun “masih dalam proses pengerjaan” dapat dikendalikan seminimal mungkin.

Sedangkan untuk Produk yang dalam proses produksi, dengan adanya pembatasan WIP ini, Persediaan (Inventory) yang diperlukan akan menjadi seminimal mungkin.

3. Mengukur Lead Time yang diperlukan

Lead Time adalah siklus waktu yang dibutuhkan untuk menyelesaikan satu unit produk ( pekerjaan/tugas) dari awal sampai akhir. Pada metode kanban, diperlukan pengukuran dan penentuan Lead Time untuk mengoptimalkan proses pekerjaan sehingga waktu penyelesaian dapat diprediksi seakurat mungkin.

別の記事

Berbagai Pemahaman mengenai Perusahaan Manufaktur

Secara umum Perusahaan Manufaktur merupakan sebuah badan usaha yang mengoperasikan mesin, peralatan dan tenaga kerja dalam suatu medium proses untuk mengubah bahan-bahan mentah menjadi...

略さずに →

Mengenal Metode Kanban dan Cara Menerapkannya

Apakah Anda familiar dengan metode Kanban? Kanban sendiri berasal dari dua kata bahasa Jepang yaitu “Kan” [看] yang artinya adalah “Melihat” atau “Visual” sedangkan kata “Ban” [板] jika diterjemahkan...

略さずに →