Punching Methods and Processes in the Metal Manufacturing Industry

📆 2021-02-22

Punching is one of the techniques used in sheet metal forming. This process is carried out with a punching machine that has the ability to cut, perforate and shape sheet metal using a punch and matrix tool similar to a press machine.

Sheet punching involves a punch press procedure for the manufacture. Punching requires a tool that matches the shape of the workpiece to be produced. The principle is the same as with a hole punch. This is an incremental procedure that involves multiple strokes to achieve complex geometries or the resulting holes from a large punch.

Metal punching process

The perforated material is usually a sheet. The roll material can also be perforated. Multiple strokes can be used together to make a complete piece with just one hit. The characteristics of the punching process include:

-

ability to produce economical holes in sheet metal during medium or high production processes.

-

Ability to produce holes of various shapes quickly.

To carry out this method, a compressive force is applied to the punch with the aim of applying pressure and it can be fed into the sheet. This process results in the initial deformation of the material to be formed, which is followed by shear stress which allows the material to crack and be cut. Finally, the resulting cut is removed from the punch.

This punching method enables fast, precise and effective processes for the formation of metal parts from various industrial sectors.

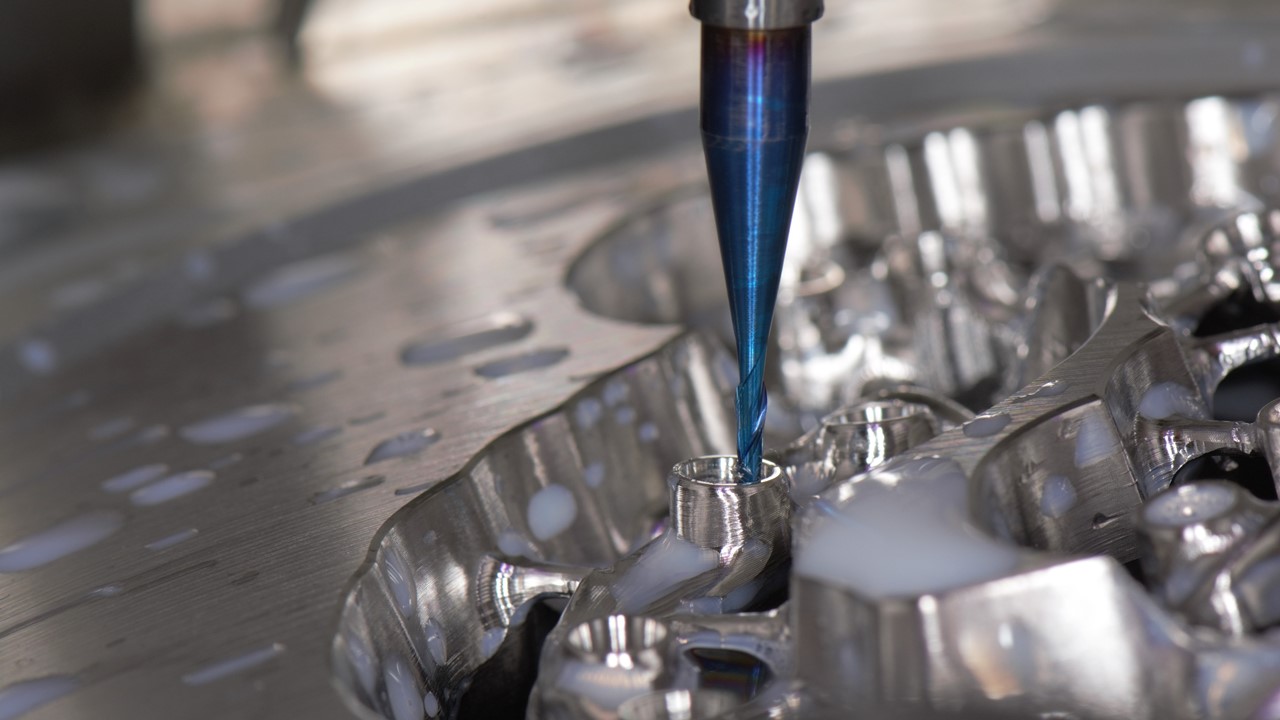

CNC punching machine

Industrial punching technology was developed in computer numerical control (CNC) punching machines. This machine allows automatic mechanical operation to punch holes in the sheet. Unlike traditional equipment which is operated by manual control via a hand wheel or lever, CNC machines are operated by commands programmed in the data storage medium.

The use of this technology allows data to be entered in a more structured way and programmatically coded to design sheet metal cuts and monitor their production processes.

Conclusion

Punching is a method that can be used for the process of cutting, perforating and shaping sheet metal as needed. In some of our Punching Solutions Duta Laserindo Metal has the latest technology to be able to develop industrial punching processes with the greatest effectiveness and assurance according to client project needs.

別の記事

What is Computer-aided Design (CAD) and Computer-aided Manufacturing (CAM)?

Computer aided design or manufacturing (CAD / CAM) is a combination of the two terms where CAD and CAM describe the software...

略さずに →

What is Laser Cutting? And How Does It Work?

Laser cutting is the process of cutting materials using a laser beam. This can be done to cut materials into complex shapes....

略さずに →