Mengenal Material untuk Welding, Bending dan Cutting

📆 2021-02-22

Sebagai salah satu perusahaan jasa welding, bending dan cutting di Indonesia, DLM menjadi perusahaan dengan Spesialisasi Laser Cutting terbaik di Indonesia. Dengan memiliki peralatan laser cutting yang canggih dan modern, DLM menjadi perusahaan cutting unggulan dan terbaik di Indonesia.

Untuk proses Welding, Bending maupun Cutting pasti memerlukan bahan material plat baja. Oleh karena itu, kami juga menyediakan berbagai bahan material kerja terbaik untuk kebutuhan para pelanggan yaitu seperti baja ringan atau mild steel, stainless steel, galvanized steel, aluminium, tembaga atau copper, kuningan atau brass dan acrylic.

Kami juga mempersilahkan apabila pelanggan telah memiliki materi sendiri, untuk kami olah sesuai dengan kebutuhan dan keperluan yang diinginkan oleh para pelanggan sampai menjadi hasil akhir.

Beberapa jenis mild steel / carbon steel :

-

SPCC ; Plat baja SPCC adalah singkatan dari Steel Plate Cold Rolled Coiled. Plat SPCC ini merupakan plat yang berwarna abu-abu terang hampir terlihat seperti plat berwarna putih. Plat ini biasa digunakan sebagai bahan pembuatan badan mobil, truk atau perangkat mobil lainnya yang dibentuk dengan metode stamping. Plat SPCC mempunyai tingkat kelenturan yang tinggi sehingga sangat lunak untuk dibentuk. SPCC sendiri dapat didefinisikan sebagai baja lembaran canai dingin dengan kualitas komersial. Jenis baja SPCC paling cocok digunakan untuk pembuatan badan mobil, peralatan listrik, dan beberapa produk peralatan rumah tangga lainnya.

-

SPHC ; Plat Baja SPHC adalah Material Baja Plate komersial yang berkualitas. Material baja plate adalah material yang berbentuk lembaran Carbon Steel (Baja Karbon) baja canai panas (Hot Rolled Steel). SPHC merupakan material yang didefinisikan dalam standar JIS G 3131. Plat SPHC sendiri berwarna gelap atau hitam. JIS G 3131 adalah standar bahan Jepang untuk baja ringan atau baja carbon. Baja canai panas komersial berkualitas adalah jenis baja yang dapat digunakan secara komersial untuk tujuan pembentukan yang juga dapat mencakup pembagian lembaran logam.

-

SPHC - PO ; Plat Baja SPHC PO adalah plat yang biasa digunakan di industri Otomotif sebagai bahan pembuatan chasis dan rangka kendaraan seperti mobil dan motor. Penggunaan plat SPHC PO untuk membuat chasis dan rangka kendaraan adalah dikarenakan material ini mempunyai kelebihan yaitu tahan flek dibandingkan dengan material SPHC. Perbedaannya sudah terlihat dari namanya diakhiri dengan nama PO, yang adalah kepanjangan dari Pickel Oil yaitu mempunyai lapisan Oli. Plat SPHC PO berwarna Abu –abu beda dengan SPHC biasa yang berwarna hitam. Plat SPHC PO dalam proses pengelasannya lebih mudah, karena hampir tidak perlu dibersihkan terlebih dahulu.

-

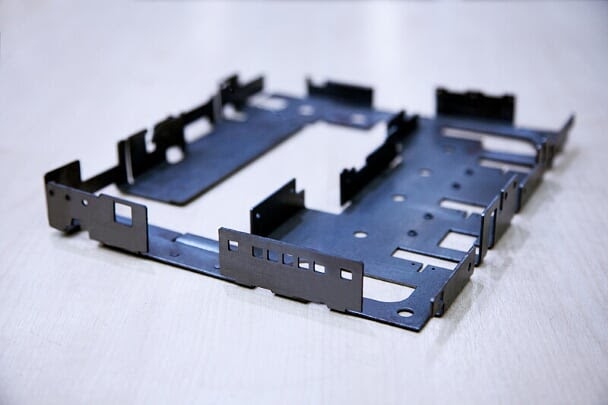

SECC ; plat baja SECC merupakan singkatan dari “Steel Electrogalvanized Cold-rolled Commercial quality”. SECC ini merupakan lembaran logam komersial yang berkualitas yang sering digunakan untuk casing komputer. SECC cocok untuk produk dengan tingkat pemrosesan rendah seperti komponen untuk pelengkungan, stamping dangkal dan pengelasan.

別の記事

Tahap Persiapan Pengelasan dan Penempatan Posisi Material Pengelasan

Ketika seorang akan melakukan persiapan pengelasan, wajib untuk memahami jenis bahan atau material yang akan masuk dalam proses. Apakah Material atau bahan tersebut mengandung...

略さずに →

Mengenal Proses dari Punching

Punching adalah sebuah teknik yang biasanya digunakan untuk melubangi material-material rata seperti kertas, plastic film, ataupun lembaran logam....

略さずに →