An Important Factors Affecting Laser Cutting Quality

📆 2021-07-19

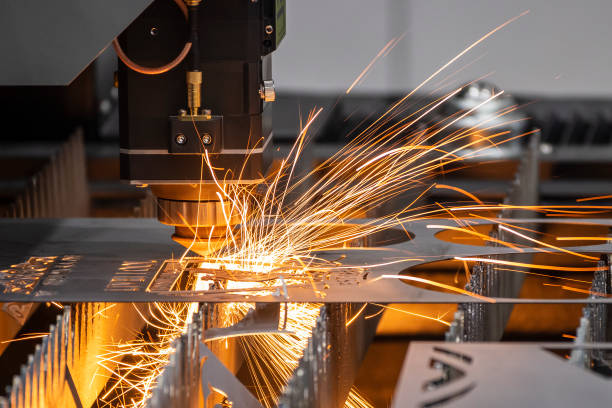

The application of laser cutting machine makes sheet metal processing technology has developed rapidly, which brings a revolutionary concept to sheet metal fabrication and processing. The results of cutting the workpiece can produce a neat cut or vice versa, rough edges or overburning. Then what are the most important factors that affect the quality during the laser cutting process?

-

Surface treatment

The most common surface treatments are galvanized, painted, anodized or covered with coated plastic. Surfaces treated with zinc tend to have thin edges. In the case of painted ones, the quality of the cut depends on the composition of the painted product. Plates coated with coated materials are particularly suitable for laser cutting. For capacitive detection to work without problems and for optimal adhesion of the layered layer (to avoid scuffing), the plated edge must always be on the top of the cutting workpiece. -

The basic microstructure of the material

In general, the finer the particles that make up the material, the better the cutting edge quality. -

Surface quality and roughness.

If the surface has areas of rust or oxidation, the cut profile will be irregular and have many fracture points. To cut corrugated board, select the maximum thickness cutting parameter. -

Thermal conductivity

When welding, materials with low thermal conductivity require less power than materials with high thermal conductivity. Materials such as copper, aluminum, and brass lose most of the heat absorbed by the laser when they are welded because heat is conducted away from the beam target point, so materials in the heat-affected zone are more difficult to weld. -

Alloy composition

The composition of the alloy affects the strength, specific gravity, weldability, oxidation resistance and acidity of the material to some extent. Some of the important elements in iron alloys are carbon, chromium, nickel, magnesium and zinc. The higher the carbon content, the harder the material to cut. -

Reflection

How the light beam is reflected on the surface of the workpiece depends on the base material, surface roughness, and treatment mode. Some alloys of aluminum, copper, brass and stainless steel sheets have high reflectivity characteristics. When cutting these materials, special attention should be paid to adjusting the focus position. -

Heat affected zone.

Laser flame cutting and laser melting cutting will cause material variation in the edge area of the material being cut.

The quality of the laser cutting is very important in the metal fabrication process. We Duta Laserindo Metal always provide the best quality for your products from the beginning to the end. If you want to do a laser cutting process for your product, please contact us and get the best product done by professional experts.

別の記事

Ways to Resist Porosity in Aluminum Alloy Laser Welding

Ways to resist porosity in aluminum alloys in laser welding process: Inhibition of welding porosity, control welding porosity and control welding porosity...

略さずに →

Get to Know: Types of Advanced Welding Technology

Welding technology types: Laser Hybrid Welding, Friction Stir Welding, Electron Beam Welding, Ultrasonic Metal Welding....

略さずに →