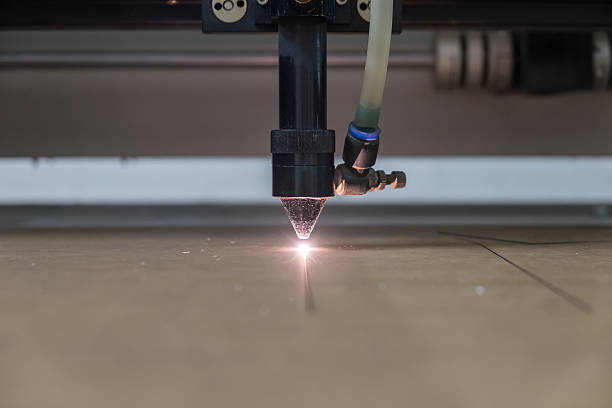

Get to know Ultraviolet (UV) Laser Marking in Metal Marking Process

📆 2021-05-05

Ultraviolet (UV) represents a band of the electromagnetic spectrum with wavelengths from 10 nm to 400 nm. They are shorter than visible light but longer than X-rays. UV wavelengths are not considered ionizing radiation, because the photons do not have the energy to ionize atoms. However, it can cause a chemical reaction that makes the substance glow.

As a result, the chemical and biological effects of UV are much more extensive than those of simple heating, and many practical applications of UV radiation are possible because of their interactions with organic molecules. Gas lasers, solid state lasers, and diodes can be used to make machines that emit ultraviolet light, and lasers are available that cover the entire UV range.

Since excimer lasers were invented, it has been possible to take advantage of intense ultraviolet light. Researchers are exploring and unraveling the unique properties of this new light source. When various phenomena involving UV energy and material interactions are discovered and optimized, practical applications emerge.

UVC, can mark a variety of materials such as glass, ceramics, plastics, and others. With high quality, UVC can mark electronic objects, microchips, and circuit boards. Apart from that, UVC is also great when used on solar panels and for proper marking of medical equipment, for example marking measuring cylinders and syringes.

Application

-

Used in the medical and pharmaceutical industries to mark low heat-resistant equipment such as plastics

-

Used in the electronics industry to mark circuit boards and microchips in high-quality <1mm font

Advantages

-

Can mark glass without risk of micro cracks.

-

UVC is efficient in power usage

Deficiency

-

UV laser marking machines are not suitable for etching or engraving in metal

-

UV Laser machines are very expensive.

One of the technologies in the marking process on sheet metal is UV laser. There are several advantages and disadvantages to the process of using this laser as mentioned above. If you want to use laser marking for your products, we Duta Laserindo Metal provide services for the best laser marking that can meet all your needs at an economical and reliable price.

別の記事

Punch Press Classification with Slider Drive Mechanism in the Punching Process

The design principle of the punch press is to change the circular motion to a linear motion. Punching by pressing the ingredients, causes them to change shape....

略さずに →

Gas Generation Trends Used in Fiber Laser Cutting

When fabricators use a fiber laser, they learn two things: how they will cut the material at a higher rate than they would with the older CO2...

略さずに →