Simple Assembly and Positioning Aids

Using positioning, you can easily establish a connection between the flat material and the tube. This allows you to weld quickly and assemble accurately due to an assignment coding system.

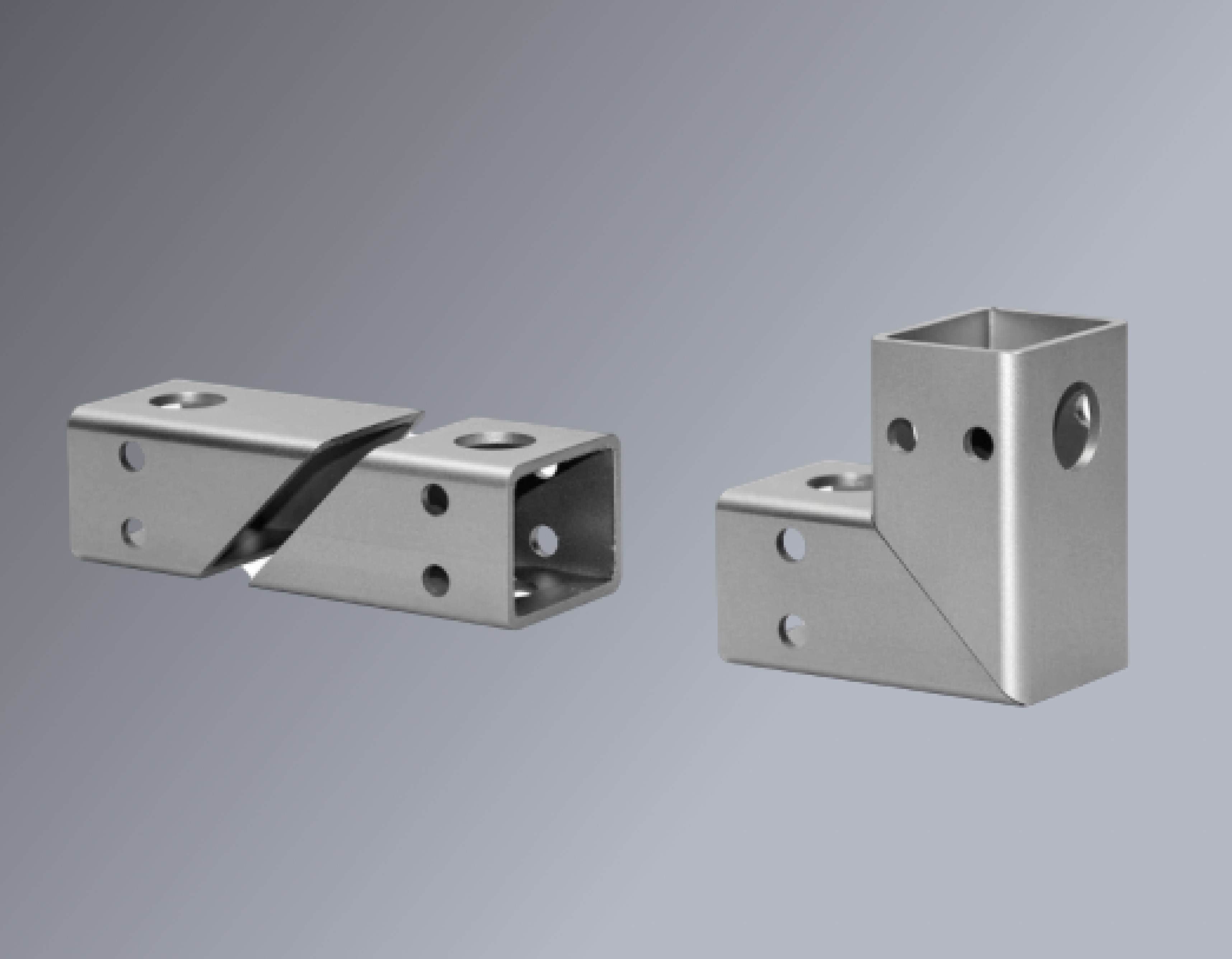

Simple Connections

If you cut tubes and profiles using lasers, you can easily join them with each another using inserts if they are user for flow functions, or attachments for load-bearing designs. In the case of corner connections, you can reduce the additional work outlay drastically using a precise bevel cut.

Other Connections

Other connections include plugs connections, as well as practical dovetails and bayonet connections. You can therefore effectively avoid complex fixtures using laser tube cutting. The joining processes that are carried out subsequently are also significantly more precise.

Bend Connections

You can achieve a fast connection composed of just one component using a practical bend connection with positioning. The possibility of a rounded corner opens up a completely new range of parts and designs. In order to ensure that components retain their correct position during and after bending, you can use a lug to fix the bend.

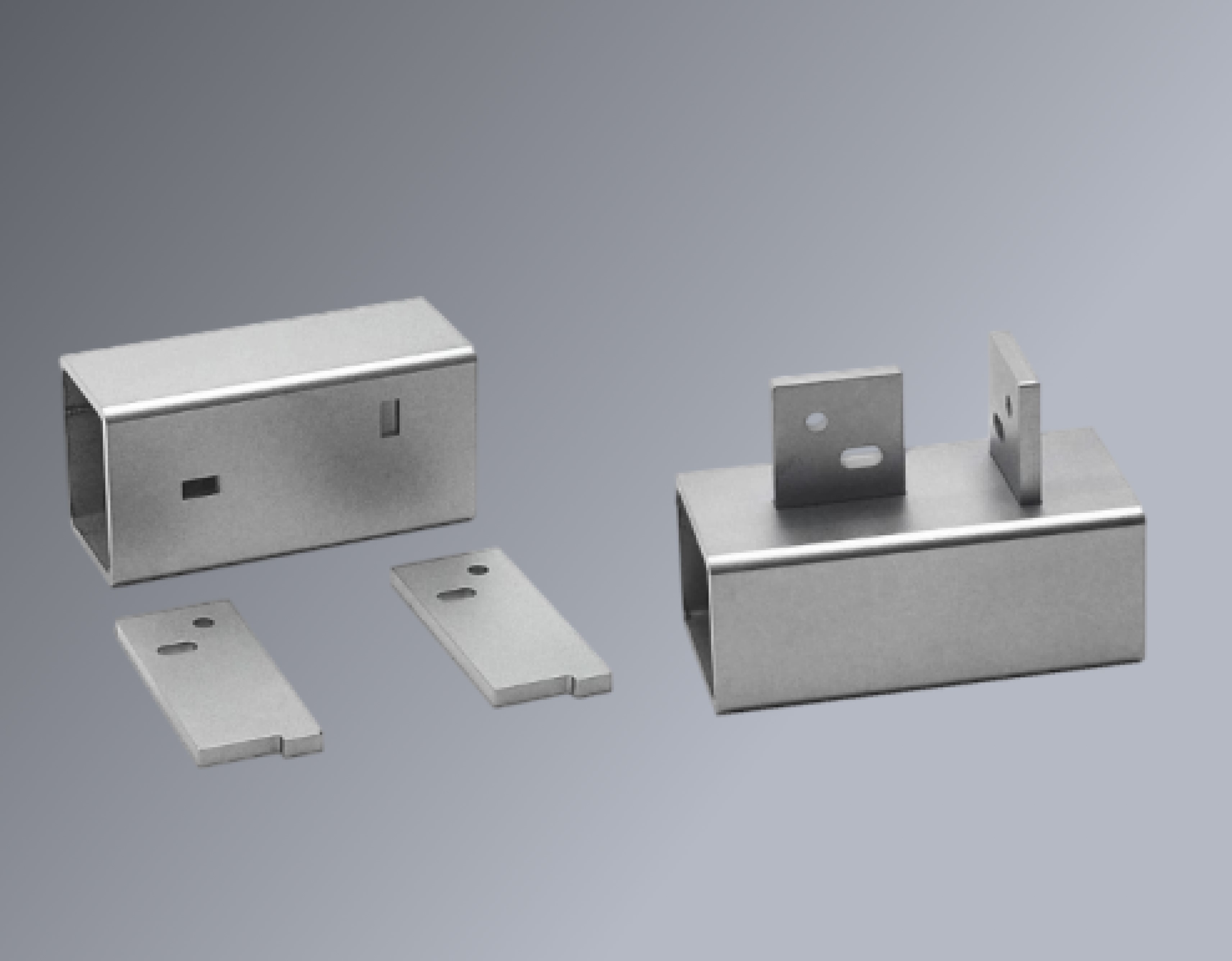

Tube - Blank Connections and flexible tube elements

Join sheet metal parts and tubes simply and quickly by using tube - blank connections. Customizable lugs allow you to attach parts easily and can also take on an assignment coding function. It is also possible to create a flexible cable guide which is cut from just one tube using the laser with the help of flexible tube elements.