Annealing

Laser is used to change the color of the surface. The annealing color depends of the material and the energy input. With annealing, the surface stay smooth, so no dirt can be deposited.

| Spesification | Stainless Steel | Mild Steel / Carbon Steel |

|---|---|---|

| Cost | ***** | ***** |

| Color | Gloss | Gloss |

| Material Thickness | >2mm | >2mm |

| Materials | Cost | Color | Thickness |

|---|---|---|---|

| Stainless Steel | ***** | Gloss | >2mm |

| Mild Steel / Carbon Steel | ***** | Gloss | >2mm |

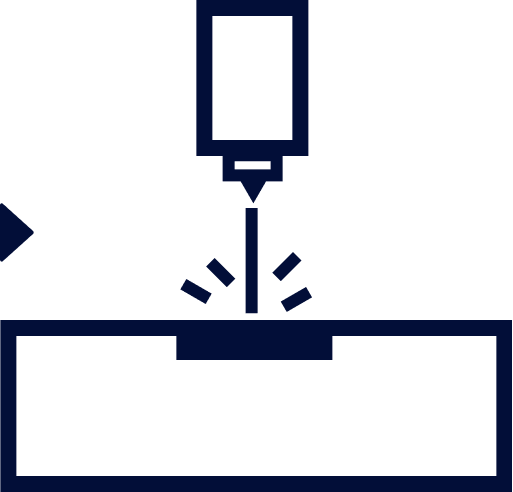

Engraving

During engraving, the laser beam removes part of the base material, this creating a depression. This may have steep or beveled edges.

| Spesification | Aluminium | Aluminium (Anodized) | Stainless Steel | Mild Steel / Carbon Steel |

|---|---|---|---|---|

| Cost | * | * | * | * |

| Color | White | White | Glitter White - MatteDark Brown |

Glitter White - MatteDark Brown |

| Material Thickness | >0,5mm | >0,5mm | >1mm | >1mm |

| Materials | Cost | Color | Thickness |

|---|---|---|---|

| Aluminium | *** | White | >0,5mm |

| Aluminium (Anodized) | *** | White | >0,5mm |

| Stainless Steel | *** | Glitter White - Matte Dark Brown | >1mm |

| Mild Steel / Carbon Steel | *** | Glitter White - Matte Dark Brown | >1mm |

Foaming

During foaming, the laser heats the plastic to cause a short melting process. During the subsequent cooling process, small gas bubles become trapped and diffuse the light that falls on them and is reflected. This type of laser marking produces a raised marking.

| Spesification | Acrylic |

|---|---|

| Cost | * |

| Color | Glitter Light Yellow |

| Material Thickness | >1mm |

| Materials | Cost | Color | Thickness |

|---|---|---|---|

| Acrylic | * | Glitter Light Yellow | >1mm |