1300KN

3000mm

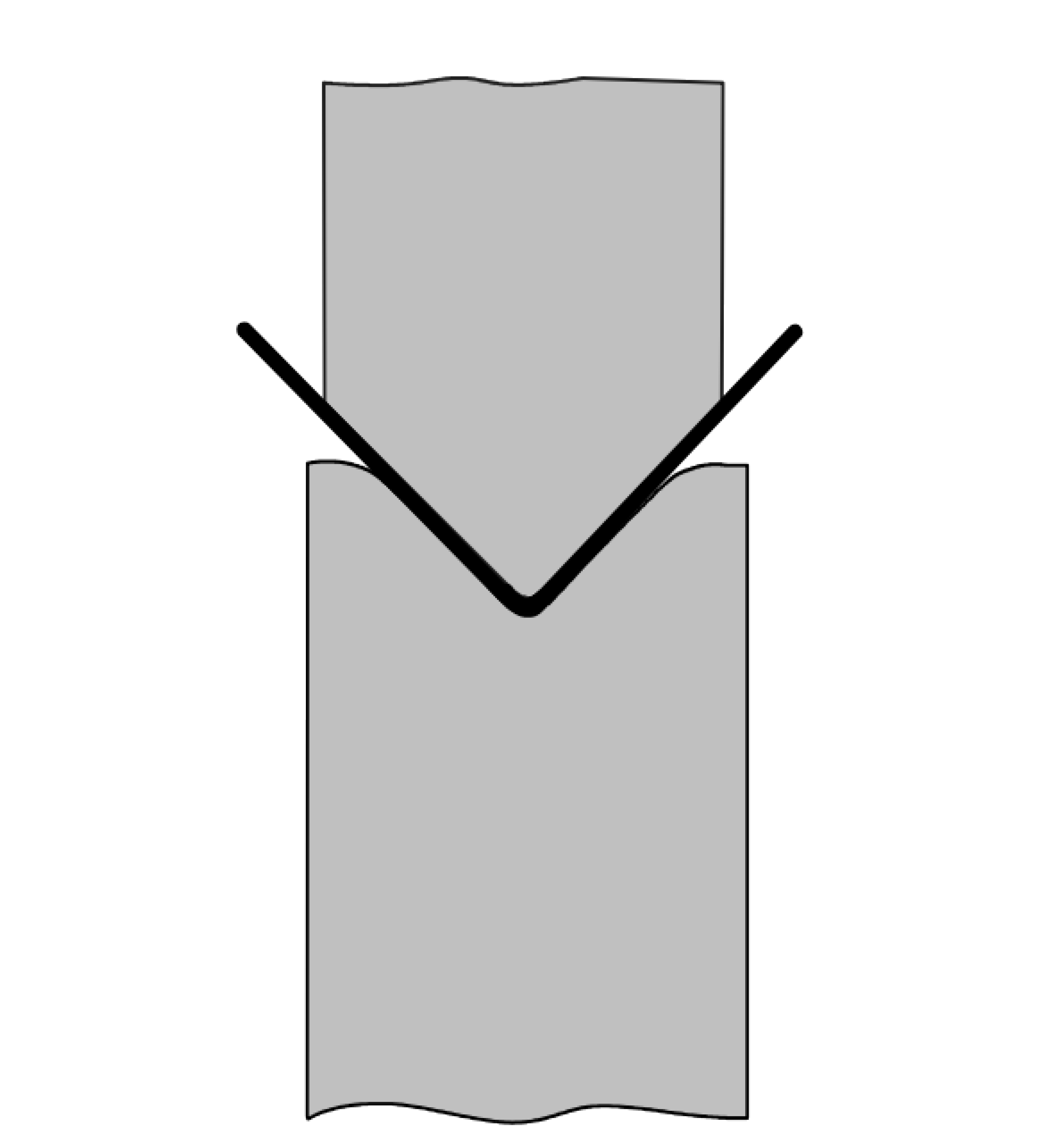

Air Bending

Air Bending is a frequently used, flexible bending method. In Air Bending , the workpieces is in contact with the upper and lower tools at three different points.

-

Any angle between approx. 32° and 180° can be produced without changing tools

Any angle between approx. 32° and 180° can be produced without changing tools -

Low bending tonnage requirements

Low bending tonnage requirements

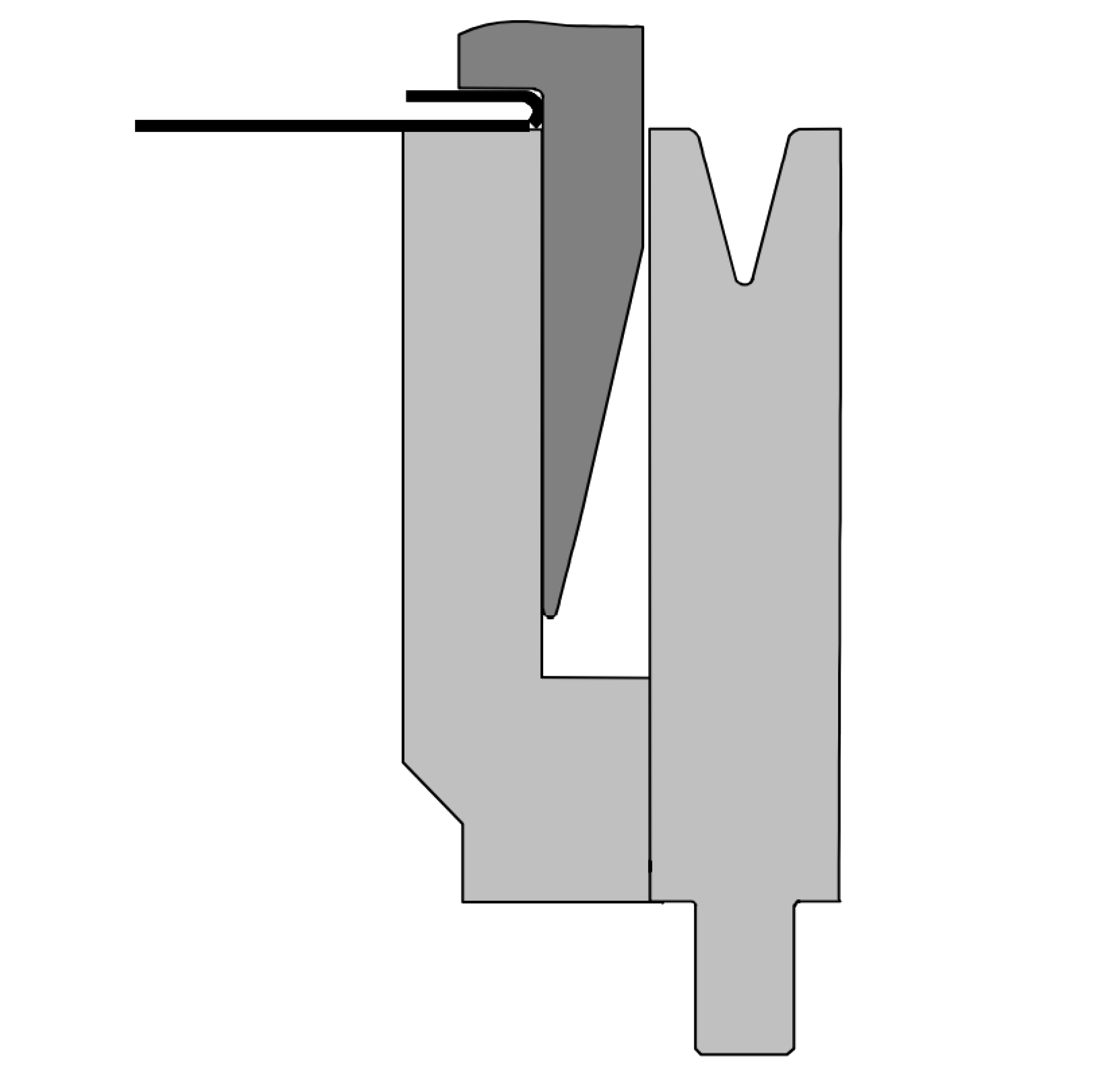

Coining

In Coining, the bend angle is produced in a form locking manner, i.e. by pressing the workpieces into a defined form (loower tool, or die). The angles of the upper and lower tools must be idntical, they determine the workpieces angle.

-

If the required inside radius of the workpiece is less than the sheet thickness.

If the required inside radius of the workpiece is less than the sheet thickness. -

If holes, cutouts or angled edges are located near or on the bending line.

If holes, cutouts or angled edges are located near or on the bending line. -

Extreme contour accuracy

Extreme contour accuracy -

Cost efficient on large series production

Cost efficient on large series production

Hemming

In Hemming, a seam is produced along a sheet edge using special tools.

-

If a seam does not need to be pressed completely flat

If a seam does not need to be pressed completely flat -

To minimize the counter-bend effect in long seam flanges

To minimize the counter-bend effect in long seam flanges -

If a defined dimension needs to be producedbetween the flanges

If a defined dimension needs to be producedbetween the flanges

Flatenning

In Flattening, a seam is produced along a sheet edge using special tools.

-

Flatenning is used when a seam is to be pressed completely flat

Flatenning is used when a seam is to be pressed completely flat