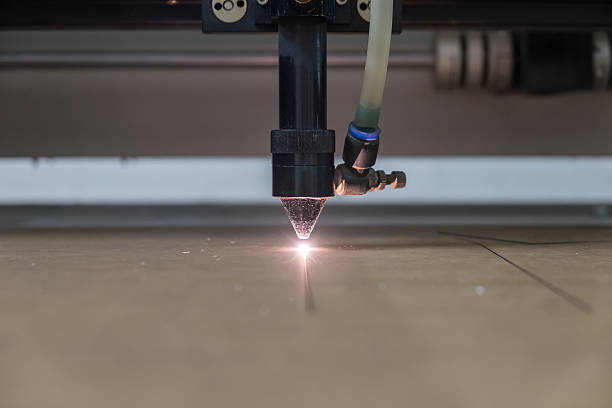

Punch Press Classification with Slider Drive Mechanism in the Punching Process

📆 2021-05-05

The design principle of the punch press is to change the circular motion to a linear motion. Punching by pressing the ingredients, causes them to change shape. Therefore, a set of molds must be used to achieve the desired shape and precision. The material is placed between them and deformed by the pressure exerted by the punch press machine.

In the punching process, there are several classifications of punch press. The following is a slider drive mechanism that is often used, including:

-

Rack Press

The use of a rack and pinion mechanism on the slide drive mechanism is called a rack-and-pinion press. Screw presses have almost the same characteristics as rack and pinion presses, and more or less the same characteristics as hydraulic presses. Previously, it was used for extrusion of pressed liners, scrap and other articles. However, rack press has now been replaced by hydraulic presses and is no longer used except in very special circumstances. -

Knuckle Press

The use of the elbow joint mechanism in the sliding drive is called a knuckle press. This type of punch press has a unique slider motion curve where the speed of the slider gets very slow near the bottom die centre. Therefore, this press is suitable for compression processing such as stamping and finishing and is therefore most often used in cold forging processes. -

Link Press

Punch presses that use multiple linkage mechanisms on a sliding drive mechanism are called linkage presses. The purpose of using the linkage mechanism is to shorten the cycle time while keeping the drawing speed within limits during the drawing process -

Cam Press

Punching machines that use a slide drive mechanism are called cam presses. This type of press is characterized by making a suitable cam shape so that the desired slide drive profile can be easily obtained. However, due to the nature of this mechanism it is difficult to transmit a large force, so this type of press has a very small capacity.

Conclusion

Now you can take a quick look at the punch press classifications, and know some of the classifications that might be used in the punching process for your product. Currently Duta Laserindo Metal has the best technicians and professionals in the field of the punching process so that it can make it easier for you to produce the best product.

Another Magazines

Types of Sheet Metal Joining Techniques

Sheet metal processing is included in the forming process, high material utilization rate, light quality, good strength, useful for electromagnetic...

See more →

Get to know Ultraviolet (UV) Laser Marking in Metal Marking Process

Ultraviolet (UV) represents a band of the electromagnetic spectrum with wavelengths from 10 nm to 400 nm....

See more →