What is Laser Cutting? And How Does It Work?

📆 2021-02-22

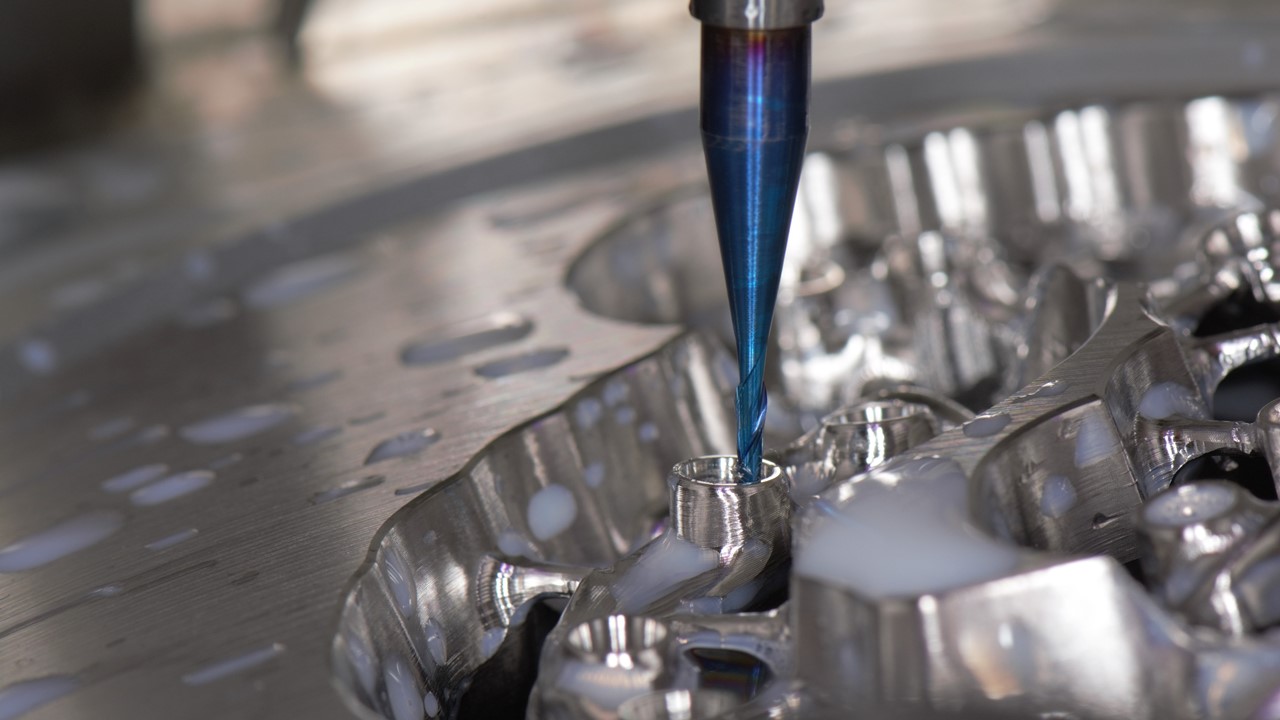

Laser cutting is the process of cutting materials using a laser beam. This can be done to cut materials into complex shapes. This process also shares many similarities with the drilling and engraving process as it involves drilling holes in the material and engraving used in subsequent processes.

These holes are basically cutouts, and you'll often see laser machines used for drilling and engraving as well. A wide variety of materials and thickness sizes can be laser cut, making for a practical and easy-toadjust process.

Why are lasers used for cutting?

Lasers are used for a variety of purposes. For example, of using it is to cut metal plates. In mild steel, stainless steel, and aluminum plates, the laser cutting process is very accurate, provides excellent cutting quality, has a very small kerf width, and allows for cutting very complex shapes.

How the laser cutter works

A laser beam is a column of very high light intensity, of a single wavelength, or color. In the case of a typical CO2 laser, that wavelength is in the infrared part of the light spectrum, so it's invisible to the human eye. The focused laser beam passes through the nozzle hole just before it hits the plate. Also flowing through the nozzle orifice is a compressed gas, such as oxygen or nitrogen.

In this process the beam must be focused precisely so that the shape of the focal point at that point is perfectly round and consistent, and is centered on the nozzle. So by focusing a large beam to a single point, the heat density at that point becomes extreme. The high power density results in rapid heating, melting and evaporation of part or all of the material.

When cutting stainless steel or aluminum, the laser beam only melts the material, and high pressure nitrogen is used to blow the molten metal out of the kerf. In a computer numerical control (CNC) laser cutter, the laser cutting head is moved over the metal plate in the shape of the desired section, thereby cutting the part off the plate.

A control system is required to maintain a very accurate distance between the nozzle tip and the cut plate. This distance is important because it determines the focal point relative to the surface of the plate you want to cut.

Conclusion

The quality of the cut can be affected by raising or lowering the focal point just above the surface of the plate, on the surface, or just below the surface. There are tons of other parameters that also affect the quality of the cut, but if everything is properly controlled, laser cutting is a stable, reliable and highly accurate cutting process.

As is done by us Duta Laserindo Metal to make prototypes and series that fit the needs of the client's project using the best laser cutting method.

Another Magazines

Punching Methods and Processes in the Metal Manufacturing Industry

Punching is one of the techniques used in sheet metal forming. This process is carried out with a punching machine that has the ability to cut, perforate and shape sheet metal...

See more →

What is Laser Tube Cutting? And how is the ability ?

Laser Tube Cutting is not an ordinary cutting process, it is capable of cutting more than just a tube and incorporating many elements and motion axes into the laser cutting process....

See more →